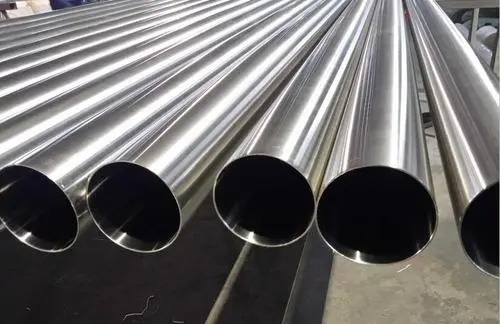

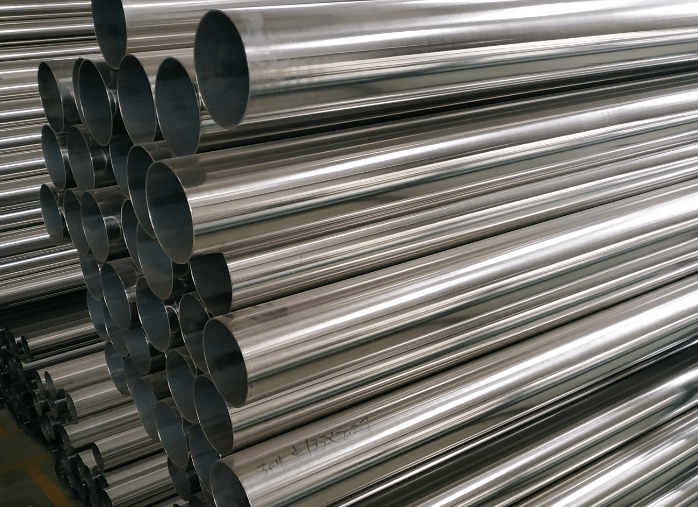

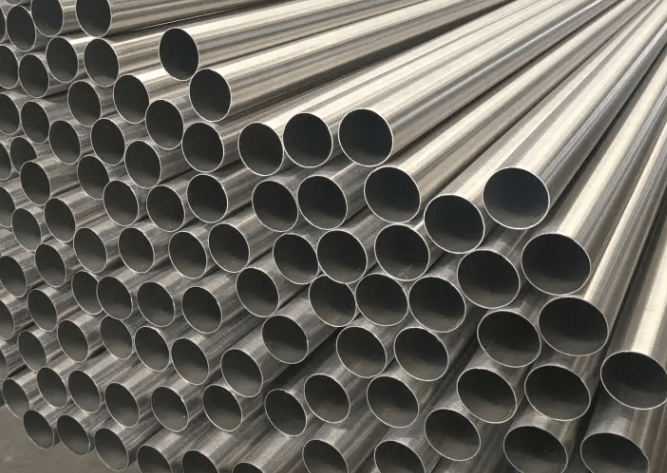

stainless steel welded pipe EFW pipe

Description

Stainless steel welded pipe, referred to as welded pipe, commonly used steel or steel strip after the unit and mold crimped forming welded steel pipe.

Steel grade: TP304, TP304L, TP316L, TP321, TP310S, TP347H, S31803, SS904L etc

Standard: GB/T12770-2002,GB/T12771-2008, ASTM A312/312M, ASTM A249/249M,ASTM A688/688M

Stainless steel welded pipe features:

First, the small-caliber stainless steel welded pipe is continuous online production, the thicker the wall thickness, the greater the investment in the unit and the melting equipment, the less economical and practical it is. The thinner the wall thickness, the lower the input-output ratio; Secondly, the process of the product determines its advantages and disadvantages. Generally, the welding steel pipe has high precision, uniform wall thickness, high external brightness inside the pipe (the surface brightness of the steel pipe determined by the surface grade of the steel plate), and can be arbitrarily measured. Therefore, it reflects its economy and aesthetics in high precision, medium and low pressure fluid applications.

Stainless steel welded pipe welding features:

According to the welding technology can be divided into automatic welding welding, manual welding. Submerged arc welding and plasma welding are generally used for automatic welding, and argon arc welding is generally used for manual welding.

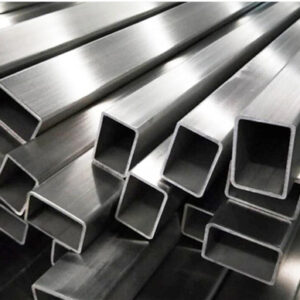

Stainless steel welded pipe classification:

According to the form of weld, it is divided into straight seam welded pipe and spiral welded pipe.

According to the use, it is divided into general welded pipe, heat exchanger pipe, condenser pipe, galvanized welded pipe, oxygen blown welded pipe, wire casing, metric welded pipe, roller pipe, deep well pump pipe, automobile pipe, transformer pipe, electric welded thin-wall pipe, electric welded special shape pipe and spiral welded pipe.